As an organization that manufactures nuclear products, we are one of the most highly regulated organizations in the world. We are regulated by the Canadian Nuclear Safety Commission (CNSC), United States Nuclear Regulatory Commission (USNRC), and Health Canada to name just a few.

Safety and Compliance

Nuclear Compliance

The CNSC regulates the nuclear industry in Canada. The Nuclear Safety and Control Act and Regulations govern nuclear substance use in Canada. We are licensed by CNSC to operate a Class 1B nuclear substance processing facility in Ottawa. The Class 1B facility is comprised of two major production operations: one for the processing of radioisotopes used in nuclear medicine, and the other for sealed sources used in cancer therapy and gamma sterilization technologies. We are accountable to the CNSC for the activities conducted under this operating license.

As a world-class provider of products and services in the regulated nuclear industry, Nordion complies with a wide variety of standards and regulations. These are set by regulatory bodies in Canada and throughout the world and define environmental, health and safety; legal; and other requirements related to the possession, handling, transportation, export and import of nuclear substances.

Licence Renewal

In 2015, the CNSC renewed Nordion’s license for the Kanata (Ottawa) facility for another 10-year period – a testament to our demonstrated standards of performance.

Community Safety

A person standing at the edge of Nordion’s Kanata (Ottawa) property has the potential to absorb 0.05 millisieverts of radiation per year, which is less than the amount absorbed during a round trip flight from New York to London.Employee Safety

Nordion is committed to providing a safe work environment for our employees and contractors.

We are committed to keeping the exposure to radiation for our employees, as low as reasonably achievable (ALARA) with social and economic factors considered.

We have implemented a conventional health and safety program to manage workplace safety hazards and to protect employees. This program complies with Part II of the Canada Labour Code, as well as to the Canada Nuclear Safety Commission (CNSC) Nuclear Safety and Control Act (NSCA) and its regulations. The program encompasses performance, practices and awareness.

Performance

A key performance measure for this Safety and Control Area (SCA) is the number of lost time injuries (LTIs) that occurs per year.

Awareness

Nordion continually promotes our conventional health and safety program to employees through a workplace poster campaign, continued emphasis on safety culture and directed campaigns to heighten worker awareness of workplace risks. Nordion conducts regular employee safety culture surveys. Nordion undertakes employee awareness surveys.

Practices

Nordion has in place a Workplace Health and Safety Committee represented by union and management that typically meets on a monthly basis. In addition, a Health and Safety Policy Committee is represented by union and management and typically meets on a quarterly basis.

Nordion continually looks for opportunities for improvements to the conventional health and safety program. Past improvements have included:

- A Job Hazard Analysis Program which is completed jointly between managers and employees performing the work

- A Manual Material Handling Program which includes instructions and training for operations employees describing correct ergonomic practices when manually lifting or handling materials

- A Working Safely with Cryogens procedure and training program

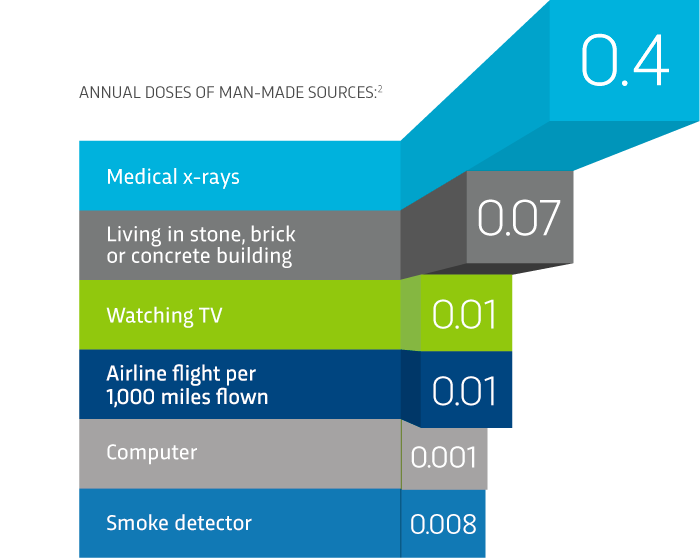

Radiation Sources

There are a variety or sources of radiation including the sun, granite countertops and potash fertilizers, just to name a few.

Cobalt-60 is used to sterilize common household products like spices, makeup—even your dog’s chew toy.

Corporate Safety

Our core purpose is to make a distinctive contribution to the health and well-being of people. In support of this core purpose, we are committed to:

Creating a workplace that enriches the health and well-being of Nordion employees

Demonstrating Environmental, Health, and Safety (EHS) regulatory excellence

Continuously improving EHS performance

Managing EHS with excellence

In an effort to meet this commitment—and exceed regulatory commitments—we maintain comprehensive waste and environmental monitoring programs.

Nordion’s Radiation Protection Program

We maintain a Radiation Protection Program in accordance with the Canadian Nuclear Safety Commission (CNSC) Radiation Protection Regulations. The program ensures that contamination levels and radiation doses received by individuals are monitored, controlled and maintained as low as reasonably achievable (ALARA). The program encompasses the following.

Application of ALARA / Worker Dose Control

All employees who work in Nordion’s licensed Class 1B nuclear facility are classified as Nuclear Energy Workers (NEWs). Some employees work regularly in the licensed nuclear facility (Active Area Personnel) while others require less frequent access (Non-Active Area Personnel).

The CNSC has set occupational radiation exposure limits for NEWs at 50 mSv of ionizing radiation exposure over a 1-year period and 100 mSv over a 5-year period.

Annually, Nordion establishes ALARA objectives with the goal to maintain radiation doses as per the ALARA principle and well below the CNSC regulatory dose limits. Recent results are provided in our Annual Compliance Report.

Estimated Dose to the Public

Nordion monitors environmental gamma radiation using dosimeters deployed at many points around the facility as well as at the residences of Nordion employees. The monitoring results have historically shown that the levels of gamma radiation at those monitoring locations are in the range of natural background. These results indicate that Nordion is not contributing to dose at—and beyond—the perimeter of the facility.

Radiological Hazard Control

Nordion has implemented a radiological survey and contamination control program which consists of routine sampling and monitoring of areas both within and outside the licensed facility. The results of this program indicate that Nordion continues to be effective. The results of the program are reported annually to the CNSC.

Radiation Protection Program Performance

Nordion sets annual targets for performance of our Radiation Protection Program. The Environmental Health and Safety Committee reviewing this performance regularly, typically every 2 months. The results of the program are reported annually to the CNSC. The CNSC’s annual assessment of this program indicates that it continues to be acceptable.

Did you know?

Worldwide, the average person receives a 2.4 mSv dose of naturally-occuring radiation annually.1

2U.S. Environmental Health Protection Agency

Transportation Safety and Security

We work diligently to manage the safe and secure transportation of our products.

Regulatory-approved Packaging

Packages designed to ship Nordion products are compliant with the Canadian Nuclear Safety Commission (CNSC) Transport of Nuclear Substances Regulations and international standards.

Depending on the use, certain package designs are subject to CNSC and foreign regulatory approvals. These transport package designs are tested against normal and worst-case accident conditions which may be encountered during transport. Package tests must follow strict testing procedures and protocols based on CNSC and International Atomic Energy Agency (IAEA) requirements. CNSC approval of a transport package design considers plans for use, emergencies, communications, and security measures.

Excellence in Transportation Security

As part of our commitment to excellence in transportation security, Nordion participates in the U.S. Department of Homeland Security’s (DHS) Customs and Border Protection (CBP) Customs-Trade Partnership Against Terrorism (C-TPAT) Program. In addition, Nordion is fully compliant with the (CBSA) Canada Border Services Agency Partners-in-Protection (PIP) program. Both of these programs involve regulatory (i.e. DHS, CBP and CBSA) inspection and audit of our security measures established to manage our product during transport.

In 2014, Nordion achieved Tier 3 Certification, the highest level of certification. By achieving a Tier 3 certification, Nordion ensures an effective, ongoing and proactive working relationship with the U.S. Customs and Border Protection and the Canadian Border Services Agency, as well as a strengthening of our reputation in Canada and the U.S. in regard to cross-border and Customs activities.

Testing of some containers includes 9-meter drop tests on a flat unyielding surface; 1.2-meter drop tests on a 6-inch diameter, 10-inch tall steel pin; puncture testing; and fire testing at 800 degrees Celsius for 30 minutes. The intent is to simulate the capacity to endure extreme crash conditions during transportation.