Learn About the Services Nordion Provides.

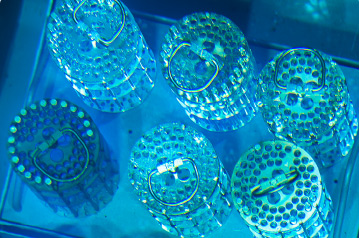

Nordion (Canada) Inc. and Nordion’s Gamma Centre of Excellence (GCE) offer companies a wide range of irradiation and sterilization services—from source supply to recycling, from irradiator maintenance to dosimetry services, and more.