Nordion, a Sotera Health company, is a leading provider of Cobalt-60. We have been processing Cobalt-60 for more than 50 years.

This is a Virtual tour of our Ottawa, Ontario, Canada campus, where Cobalt-60 is processed.

This is a Virtual tour of our Ottawa, Ontario, Canada campus, where Cobalt-60 is processed.

1

Nordion, a Sotera Health company, is a leading provider of Cobalt-60 used in the sterilization and irradiation process for the medical device, pharmaceutical, food safety and high-performance materials industries.

We are a leading provider of gamma technologies that benefit the lives of millions of people in 40 countries around the world. We’ve been delivering safe, high-quality products to global customers for 70 years.

Our head office and main processing facilities are in Ottawa, Ontario, with an additional facility in South Oxforshire, England. This Virtual Tour is of our Ottawa Facility.

2

There are two main buildings on the Nordion campus—the Roy Errington Building (the name is a tribute to a founder/president) and the Nordion Operations Building.

Throughout our campus are office spaces, meeting rooms and cafeterias for our employees, and manufacturing space.

Our commitment to improving the health and wellbeing of people is reflected in our day-to-day corporate culture. Just one of the many healthy initiatives on our campus is a fitness centre which is open 24 hours a day 7 days a week for cardio training, muscle strength and toning, and group fitness.

3

We are a leader in gamma irradiation technologies. We process two types of Cobalt-60. The first is Cobalt-60 used to reduce or destroy harmful micro-organisms from a wide variety of products. The second is medical (HSA) Cobalt, which is used to treat cancers of many different types in all parts of the body, as well as non-cancerous conditions.

Nordion’s Cobalt-60 is used in many different areas where sterilization is essential to prevent disease. The most common applications include the sterilization of single-use medical devices, micro-organism reduction on lab ware and consumer goods, and irradiation of food for safety import/export control.

Irradiation of food kills bacteria, like E.Coli, Salmonella and Listeria, and prevents illnesses. Cobalt-60 irradiation eliminates potentially harmful pests while maintaining the quality of grain, fruits and vegetables, and spices. Let’s take a look at the complete Cobalt-60 production process—from the raw material to its final use in gamma irradiators.

*Source: International Irradiation Association (iia)

Nordion’s global supply chain and distribution capability is unparalleled.

Cobalt-60 raw material is produced in nuclear reactors in Canada and other parts of the world. The Cobalt-60 is shipped to Nordion’s facility, where it is processed into sealed sources.

Once the Cobalt-60 arrives at Nordion, it is removed from an outer encapsulation, welded into a new double-encapsulated source called a C-188 and shipped to our customers’ sites for use in irradiators. The next several frames in this virtual tour describe the process in more detail.

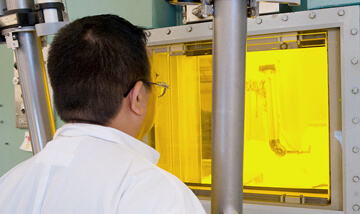

Here’s an image of a technician standing outside of what we call a “hot cell,” inside of which raw material is introduced. We have various cells, each of which serves a different purpose in the processing of Cobalt-60. They are built to contain radioactive materials and to provide shielding to the immediate vicinity.

Inside the cell is where we encapsulate the Cobalt-60. The machine in the technician’s right hand activates “hands” inside the cell that are called manipulators.

Highly skilled technicians pick up items as small as a pin using manipulators. It takes almost 1 year of training to use manipulators properly.

It’s hard to tell when looking through the window, but the windows are made of numerous panes of glass for a total thickness of several feet, and they are specially engineered to avoid distortion. The high-density walls are several feet thick. The shielding within the wall and window protects our employees from radiation.

There are many safety precautions built into the facility and our processes include employee training, monitoring systems, cleaning, and decontamination processes, facility testing, and more.

Nordion has been shipping Cobalt-60 to customers throughout the world for over 50 years safely, efficiently, and reliably.

With safety as our #1 priority, Nordion has an extensive fleet of regulatory-approved lead and steel certified containers that meet all international shipping requirements.

While we have a number of shipping containers, the image here is our F-231. Every shipping container is state-of-the-art and undergoes stringent quality assurance and safety testing. To design, develop, test, and license a container can take over 3 years.

Testing includes 9-meter drop tests on a flat surface, 1-meter drop tests on a pin, puncture testing, and fire testing at 800 degrees for 30 minutes. The intent is to simulate the capacity to endure extreme crash conditions during transportation.

As well, the containers are shipped back to us for re-use. We test them when they come back, clean them, and maintain them. Nordion provides one-stop cradle-to-grave services.

Through long-term supply of Cobalt-60, every day we make a distinctive contribution to the health and well-being of people around the world.

4

There are many safety precautions built into our facility and our processes including employee training, monitoring systems, cleaning and decontamination processes, facility testing, and more. We do this to protect people and the environment.

Remember the hot cells in the gamma area? Our hot cells include a state-of-art ventilation and airflow monitoring system. We monitor the airflow and feed data to a central safety monitoring system. Wondering where the air goes? Air from this facility goes through a series of filters before mixing with the outside air.

The safe amount of radioactive material we can put in the outside air is strictly controlled by the Federal regulators. Nordion releases only 5% of the allowable safe limit. Our filters are tested twice annually for effectiveness; however, the performance of our ventilation system is monitored constantly by a series of alarm detectors.

Nordion is committed to environmental health and safety.

Ten dosimeters were placed around the Ottawa campus-some in neighbouring homes-to measure if radiation doses above background levels have occurred. There have been no instances of exceeding regulatory limits.

for taking the Virtual Tour of our Ottawa campus. We value your opinion.

If you have feedback to share with us, we invite you to click on the link below and tell us what you think.